Renyi iron foundry both have handmade clay sand casting pattern and resin sand casting pattern.

There are automatic & manual molding line, for large QTY, Adopt automatic molding line for casting production, that will greatly lower the casting cost and speed up the lead time,

however, for small QTY order, will use our manual molding line for casting production, that means the cast with dozen or hundred in a short lead time.

- AISI/ASTM 60-40-18

- AISI/ASTM 65-45-12

- AISI/ASTM 80-55-06

- EN-GJS-400-18

- EN- GJS-400-15

- EN- GJS-450-10

- EN- GJS-500-7

- EN- GJS-600-3

- ASTM A48

- CLASS 30A

- CLASS 35A

- CLASS 40A

- CLASS 45A

- EN-GJL-150

- EN-GJL- 200

- EN-GJL- 250

- EN-GJL- 300

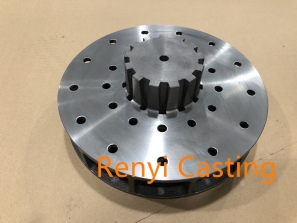

Sand casting is a procedure that makes use of non-reusable sand mold and mildews to create metal spreading’s.

It is a common manufacturing approach for metal parts of all dimensions, from a couple of ounces to several tons. Iron Sand casting isn’t only versatile in the dimension of its items — it can additionally produce incredibly complicated or detailed spreading’s, as well as can be utilized to cast almost any kind of steel alloy.

Offer remarkable high quality iron sand castings components and elements to markets including vehicle, transportation, mining, petrochemical, electrical, power and also others. We cast sand casting components approximately 10 metric loads. Materials can be aluminium alloy, ductile iron, brass alloy, Grayiron, etc.

Provide high accuracy CNC machining and also other additional procedures. We also offer quick model solutions. Both low to high-production quantity sand spreading rate.

Feedback RFQ

Our professional sales team will feedback your RFQ within 12 hours, and give you the Quotation within 48 hours max. if the drawing and specification is all in details.

Lead time for Mould and samples

For normal project, we can complete Mould and supply the 1st article sample within 30 to 40 days.

For urgently project, we can complete the Mould and Sample within 20days max.

Payment terms for Order

For Mould/tooling and sample : 50% deposit pay by Order, rest 50% pay after sample approval.

For production Order for new Customers : we request 30% down payment, rest 70% pay by copy of Original B/L copy. For long lasting regular customer, we can give better payment terms, such as 100% pay after delivery or by B/L copy.

Customer service

How to solve non-conformity or other dispute if raise up

Quality is our life, during production, from QC to all our operators, we take quality as first thing, during the 1st Article sample and production, our team maintains the quality with same high level. However, no matter how we strictly to the quality, it is a possibility to supply non-qualified shipment to our clients, if this unhappy thing be happen, we will try our very best to negotiate with our customers and solve it as following : and try to reduce our customer’s loss as less as possible, then we will both earn experience from the lessons and definitely for our future repeat order, we can supply the excellent quality shipment.

If the Order shipment have any quality problem, we will be open to discuss with clients, and manage to solve the non-conformity at our best efforts. If Client can repair the parts at locally, we can compensate back to re-pair local re-work cost. If can not be re-worked, we will return back the 100% money or issue a Credit note for the replacement of amount. Or replacement the new QTY of shipment to client. And if the non-conformity is not critical, customer can compromised accept them, we’re happy to discuss friendly with customer by give some discount to close this non-conformity shipment.